1. The floating ball valves

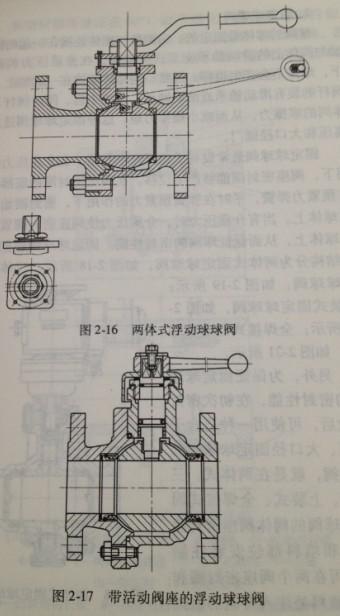

This ball valve ball is floating, made two seat bearing, in under the action of medium pressure, the sphere itself generates a certain amount of displacement, and tightly pressed on the outlet valve seat ring, ensure outlet seal; If standard requirement for inlet side seal, sleeve seat is designed to take activities, on the back seat are preloaded spring floating ball valves. In the form of floating ball valves according to the body of one-piece floating ball valve (ball valve) only one body as shown in figure 2-15; Two postures floating ball valve (the valve body and the left and right two body) as shown in figure 2-16; Sleeve seat belt activity of floating ball valve, as shown in figure 2 to 17.

Floating ball ball valve of simple structure, good sealing performance. Due to the body of work medium pressure to all the outlet valve seat seal, seal biya is not easy to control, therefore, the mechanism of ball valve is only applicable to the water and low pressure valve.

Floating ball valve faults are: assembly pre-tightening force is not easy to control, but also need to use different thickness of the gasket to adjust, assembly difficulty, manufacturing high accuracy requirement, and at the same time operating torque is bigger also.

2 fixed ball valve

Ball of the ball is fixed, is composed of two sections together with the ball of the fixed shaft and bearing lubrication on the bearing ball; when closed, in the medium under pressure, the ball does not produce displacement, usually, together with the ball on the lower stem, a sliding or rolling bearings, a decrease of Rev. Closed, the friction between the stem and body, thereby reducing the operating torque, the fixed ball valve suitable for high pressure and large diameter valves.

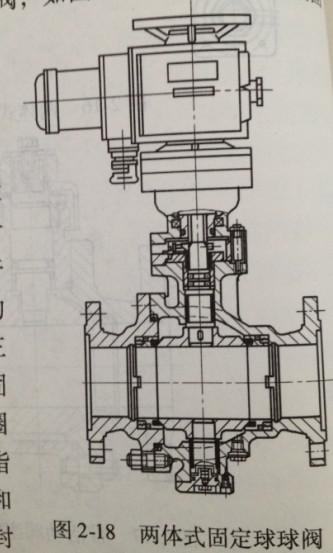

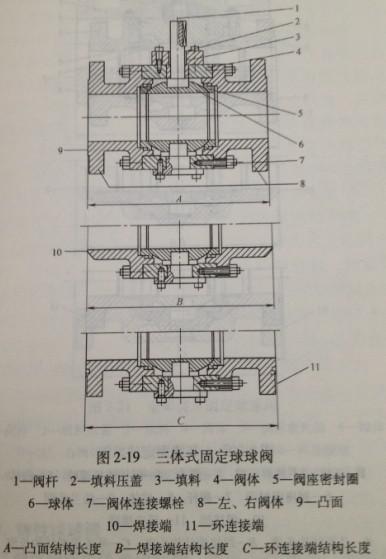

Fixed ball valve is usually provided with movable seat seal ring, in the medium under pressure, the valve seat sealing ring can produce a shift in the seat, the sealing ring is arranged in the sphere. When the medium pressure, medium pressure and the valve seat sealing ring is tightly pressed on the body. In order to ensure the valve sealing performance. Fixed ball valve is divided into two type fixed ball valve according to the body of the organization, as shown in Figure 2-18; three body type fixed ball valve, as shown in Figure 2-19; jacket type fixed ball valve as shown in Figure 2-20; all welded type fixed ball valve, as shown in figure 2-21.

In order to ensure the sealing performance of fixed ball valve, in the initial seal failure, can use a suitable for high pressure, large diameter fixed ball valve valve grease, is sealed in the valve body and valve seat two type, body type, jacket type, welded type fixed ball valve ring and filler installation sites of fat injection valve. Sealing ring and the valve stem packing in the two seat into the sealing grease specially, the sealing grease to ensure that does not melt at 50 ℃, keep the original performance. The sealing grease in the two sealing surface and valve stem packing to form a layer of oil film, not only enhance the sealing performance, reduce operating torque, fixed ball valve with fat injection valve, request to the fixed ball valve injection at intervals of fat.